Buell Automatics specializes in precision CNC machining and multi-spindle screw machining services. Our company has been producing precision products for over 50 years. We provide fast and cost-effective manufacturing solutions across multiple industries and applications.

Machined fittings and connectors are one of our most popular services. Our CNC machining and multi-spindle screw machining experience facilitates the fabrication of high-quality fittings and connectors from a variety of material grades. The fittings and connectors are used in applications such as:

- Fuel/Water/Steam/Chemicals/Fluids

- Valves/Hydraulics/Solenoids/Pneumatics/Pumps

- High Pressure/Low Pressure

- Quick Disconnect/Adaptor-Port/Pipe/Compression/Flanged/Welded/Brazed/Flared

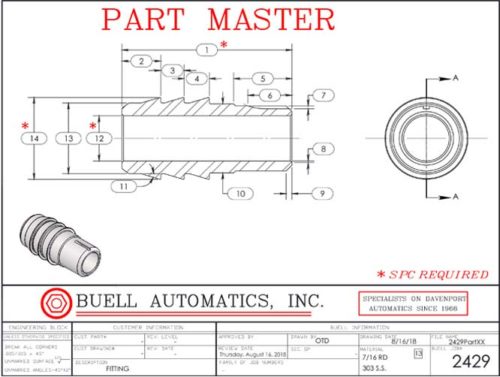

Case Study: Stainless Steel Automotive Fuel Emissions Fittings

Since 1966, Buell Automatics has been helping companies meet all kinds of small part needs, assisting clients throughout every step of the manufacturing process — from initial design to finished product. To better illustrate how we work with customers to craft high-quality, customized solutions, we’ve outlined a case study below.

The Problem

A company recently approached us about the assembly of their automotive fuel emissions fittings; before contacting us, they had been procuring them from another manufacturer, who used cold drawn plated steels to create the parts.

The customer was new to Buell and looking for a change; the cold drawn plated steel fittings were resulting in long lead times and inconsistent, unreliable quality, thereby putting larger systems in danger. So, the company requested that we use stainless steel, rather than cold drawn plated steels, in the assembly of these key automotive components.

The Solution

Typically, stainless steel is a difficult material to work with, but our expert team was able to create a reliable, high-quality solution working with our Davenport five-spindle screw machine, which was enhanced with the use of our proprietary coolant through drilling. This coolant allows us to machine more complex parts at faster turnaround times and lower costs.

Our expert manufacturing engineers and Davenport machine setup and production personnel completed several processes to ensure the highest-quality, most reliable results possible — turning, deep hole drilling, milling, facing, and cutoff. Though our team initially had difficulty getting the slot (leak path) in the fitting, they quickly found success after switching from broaching to milling. After completion, we did a comprehensive visual inspection to ensure optimal quality.

The Result

Ultimately, through the use of our Davenport machining, in-house coolant, and deep hole drilling capabilities, we were able to reduce the production time needed to manufacture the fitting while also providing our client with significant cost savings.

The customer was very pleased with the final stainless automotive fuel emissions fitting and has since partnered with us for additional projects. In fact, this client recently submitted a request to manufacture a new fuel emissions fitting from 303 stainless steel. They were also able to sell the stainless steel fuel emissions fitting to their own customers, generating new business for their company as well as our own.

Precision Fittings with Buell Automatics

It’s essential to choose the right adapter, pipe, and port fittings for high-end fuel line systems and transportation equipment. Straight and tapered threads require different sealing methods. Buell Automatics can fabricate high-quality fittings with both straight and tapered threads to meet your company’s needs. Contact us today to learn more or receive a quote for your order.